The Role of Wind Tunnel Testing in Cycling Equipment Design

In the world of cycling, every factor affecting performance can make a significant difference, and aerodynamic efficiency is paramount. This is where wind tunnel testing comes into play. Engineers and designers utilize wind tunnels to analyze how equipment responds to various airflow conditions. By simulating real-world wind conditions, they can gather data that informs decisions regarding bicycle frames, helmets, and clothing. The controlled environment of the wind tunnel allows for precise measurements, enabling the assessment of different materials and shapes. Utilizing wind tunnel testing not only helps identify the fastest designs but also enhances rider comfort and stability. As cycling technology continues to evolve, the importance of these tests becomes even clearer, pushing boundaries in speed and performance. Cyclists aim to reduce drag, and studies show even minor improvements can lead to significant competitive advantages. Thus, understanding the aerodynamic properties of cycling gear is a crucial step in developing high-performance solutions that meet the needs of athletes at all levels. The integration of wind tunnel data has become an essential component for manufacturers looking to gain an edge in the competitive cycling market.

Further enhancing the significance of wind tunnel testing, certain variables come into play during these assessments that directly influence findings. Factors like rider position, gear selection, and even environmental conditions contribute to the results gathered in a wind tunnel. Hence, real-world validation is often necessary to complement these data sets. Cyclists outfitted with cutting-edge technology can experience varied airflow that may alter their riding dynamics significantly. Additionally, ergonomic concerns arise: gear fitment shapes and styles not only impact performance but also rider safety and comfort. This balance of performance and comfort underscores the comprehensive approach wind tunnel testing mandates. Brands like Specialized and Trek are leveraging this science to refine products consistently. In practice, the information gleaned from wind tunnels informs the design of everything from clothing materials to aerodynamic frame shapes. As manufacturers adopt this data, their capabilities to forecast trends and rider experiences improve dramatically. Continuous innovation allows for timely updates in equipment designed to resonate with changing industry standards and cycling regulations. This places wind tunnel testing at the forefront of competitive cycling development, ensuring that every piece of gear offers an optimal balance of speed and functionality.

The Process and Methodology of Wind Tunnel Testing

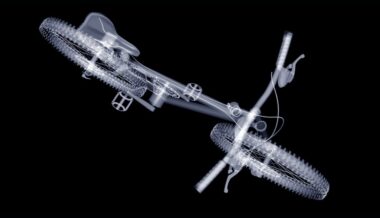

Wind tunnel testing involves a systematic methodology that helps cycling engineers obtain accurate aerodynamic data. First, a model, which might be a bicycle frame or rider, is mounted securely in the wind tunnel. It’s essential to simulate how real riders interact with their bicycles under various wind conditions. The wind tunnel generates controlled airflow, which is measured in terms of speed and direction. Sensors collect data on drag forces acting on the model during tests, facilitating a thorough analysis. Typically, computational fluid dynamics (CFD) simulations complement physical testing, providing insights into airflow behaviors. Experimenters refine designs based on iterative results, allowing for numerous variations to be examined efficiently. By analyzing pressure distributions on surfaces, teams can pinpoint areas requiring adjustments, increasing aerodynamic efficiency. This continuous feedback loop fosters innovation and design optimization. The combination of empirical findings and software support helps manufacturers stay competitive and responsive to consumer needs. Taking a holistic view from initial design to final testing, wind tunnel methodology plays a vital role in ensuring that cycling equipment meets the highest standards regardless of the athlete’s skill level.

Advancements in wind tunnel technology further enhance the capabilities of testing processes. State-of-the-art facilities are equipped with sophisticated data acquisition systems, enabling more detailed and faster analysis than ever before. They utilize advanced instrumentation like pressure taps, balance systems, and flow visualization techniques. High-resolution cameras capture airflow patterns around the bike and rider, providing visuals that help identify performance weaknesses that might not be immediately obvious through data alone. These modern wind tunnel systems increase the fidelity of outputs, allowing for innumerable design iterations in shortened timeframes. The push for lighter, stronger materials has led researchers to continuously explore novel options that improve performance while keeping the cyclist’s comfort in mind. This exploration goes hand in hand with user experience; effective integration of new technologies leads to better products for both elite and recreational riders. As cycling enthusiasts demand more from their gear, manufacturers who invest in premier wind tunnel facilities are positioning themselves for success. Staying on the cutting edge requires not only technological investment but also a commitment to refining athlete-centered product designs based on wind tunnel insights.

Real-World Applications: From Pro Teams to Everyday Cyclists

Wind tunnel testing benefits all levels of cycling by informing product development across the board. Professional cycling teams, particularly those competing at the WorldTour level, have integrated wind tunnel testing directly into their training regimens. Access to this data allows them to choose equipment that not only enhances speed but also matches their individual riding styles. Ultimately, this can create a massive impact on the success of their performance in races. For everyday cyclists, the enhancements trickle down through improved consumer gear developed with wind tunnel-tested data. Innovations often lead to more affordable options that carry the benefits of advanced designs previously reserved for elite athletes. Recreational riders see a noticeable difference in their experience thanks to refined gear that optimizes every pedaling effort. Features developed through wind tunnel data, such as efficient helmets or aerodynamic apparel, ensure that enthusiasts can significantly enhance their performance. As the popularity of cycling continues to rise, manufacturers’ commitment to wind tunnel testing reinforces their dedication to delivering exceptional equipment tailored for the needs of both competitive and casual cyclists alike.

Educational institutions and research organizations are also taking advantage of wind tunnel technology. Universities have established dedicated testing facilities that foster collaborations between engineering students and cycling industries, producing new ideas and innovations. Through academic partnerships, students gain hands-on experience while companies benefit from fresh insights that can lead to pioneering advancements in cycling technology. Some even focus on developing sustainable materials that maintain aerodynamic properties while reducing the environmental impact. These endeavors not only serve as an incubator for ideas but also prepare the next generation of engineers who will shape the future of cycling equipment design. As cycling becomes increasingly technology-driven, the challenge for engineers lies in balancing performance with sustainability. The knowledge obtained through wind tunnel testing will play a critical role in this evolution, encouraging designs that respect environmental standards. As the community of cycling professionals grows, it relies on wind tunnel insights to navigate challenges and seek innovative pathways toward success, ensuring that the sport remains at the forefront of engineering excellence and environmental responsibility.

The Future of Cycling Equipment Design

Looking ahead, wind tunnel testing is poised to become even more integral in cycling equipment design as technologies advance. The shift towards integrating artificial intelligence and machine learning can provide deeper predictive analytics on designs, further optimizing performance. With the potential to analyze vast datasets, these advancements can rapidly process results much quicker than traditional methods. As computational models enhance accuracy, wind tunnel tests can refine equipment variations almost fluidly, resulting in faster innovation cycles for companies. Additionally, athlete feedback regarding comfort and performance can integrate seamlessly with testing outcomes, allowing for a complete view of design efficacy. The continual drive for better aerodynamics, lighter materials, and improved comfort ensures that the cycling landscape remains dynamic. As global interest in cycling grows, companies willing to invest in cutting-edge technologies like advanced wind tunnel testing will remain competitive in the marketplace. The future promises to meld scientific inquiry with practical application in the quest for peak performance. Engaging with evolving technology while maintaining rider feedback will be the key to success in realizing the full potential of wind tunnel insights in cycling gear production.

In conclusion, wind tunnel testing represents a crucial component in the evolution of cycling equipment design. Not only does it facilitate the exploration of aerodynamics, but it also enhances cyclists’ overall experiences and helps them achieve performance goals. As technologies evolve, so too will the methodologies surrounding wind tunnel assessments, leading to unprecedented levels of innovation and refinement in cycling gear. The benefits extend from professional cyclists racing at high speeds to casual riders seeking comfort and efficiency. Every advancement made through wind tunnel testing influences design standards and market expectations alike, ensuring that cyclists receive the best technology available. As new materials and designs emerge, the role of wind tunnel testing will remain vital in navigating the complexities of this dynamic field. The interplay of engineering science, technology, and cyclist insight will continue to shape the future of cycling equipment. With a commitment to pushing boundaries through testing, the cycling industry can expect exciting developments ahead. Regardless of a cyclist’s level, wind tunnel testing will continue to inspire designs that promise speed, efficiency, and enhanced comfort with each ride.