The Influence of 3D Printing on Sports Equipment Design

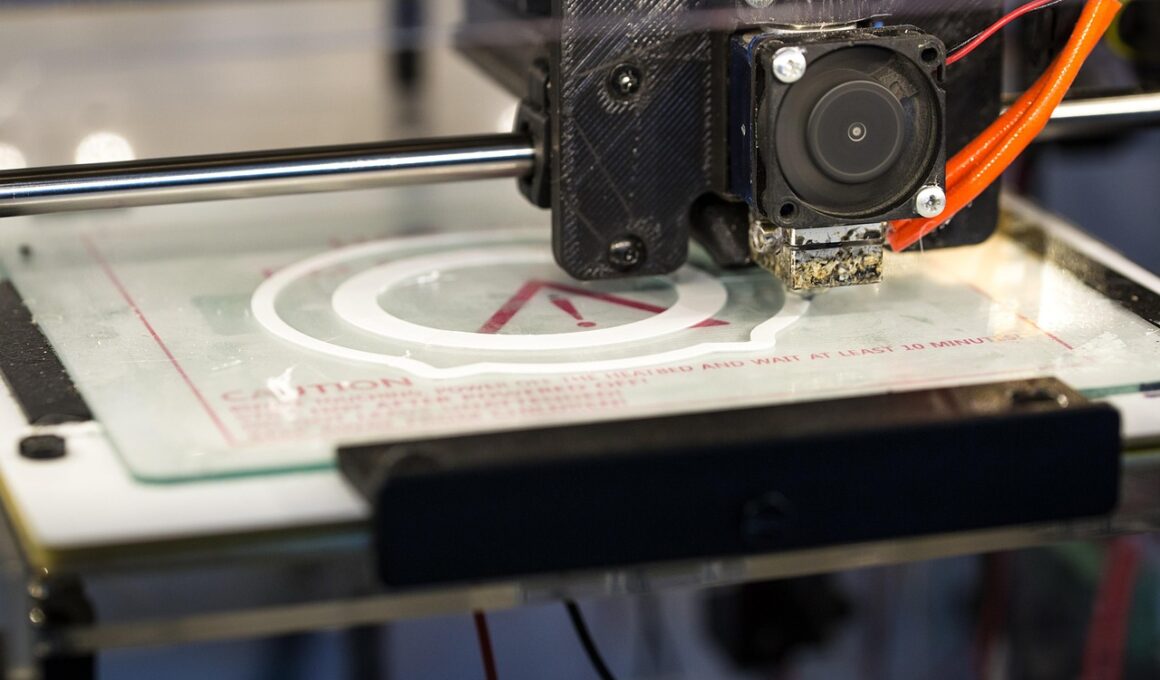

3D printing technology has revolutionized various industries, and sports equipment design is no exception. With the capacity for rapid prototyping, manufacturers can now create customized sports gear that meets the specific needs of athletes. This includes anything from personalized running shoes to specialized helmets for contact sports. Through layer-by-layer additive manufacturing, designers can produce lightweight yet robust materials, which is essential in optimizing performance. The ability to iterate designs quickly allows for more innovative approaches, ultimately pushing the boundaries of what is possible in sports gear. Athletes are no longer constrained by traditional manufacturing limits; their equipment can be tailored to their unique body shapes and performance styles. Moreover, 3D printing also supports sustainable practices by reducing waste associated with traditional manufacturing processes. In essence, this technology not only enhances athletic performance but also promotes environmental responsibility. The versatile nature of 3D printing continues to provide opportunities for creative breakthroughs in sports technology, making it a critical field for ongoing research and development. Collaborations between designers, engineers, and athletes are vital for utilizing this technology to its fullest potential, especially in a highly competitive sports environment.

One of the most significant benefits of 3D printing in sports equipment design is the ability to create lightweight and durable products. Traditional manufacturing methods often use materials that can add unnecessary weight to equipment. 3D printing, however, allows for the creation of intricate structures that maintain strength without heavy components. This is particularly beneficial in sports like cycling and running, where even minor reductions in weight can lead to improved performance. Athletes can enjoy gear that does not hinder their speed or agility. For example, designs can incorporate lattices or honeycomb structures that not only reduce weight but also improve shock absorption. Additionally, early adopters of 3D-printed sports equipment have reported increased comfort as the gear better fits individual body types and preferences, showcasing a move away from one-size-fits-all designs. Personalized gear can lead to enhanced performance metrics as athletes are equipped with the most suitable sports gadgets tailored entirely to their specifications and preferences. As the technology continues to develop, the possibilities for customization will only expand, changing how athletes approach their training and competitions.

Customizability and Personalization

The customizability of sports equipment through 3D printing offers immense advantages to athletes. The ability to produce products tailored specifically to an athlete’s anatomy leads to significant performance benefits, minimizing injury risks. With 3D scanning technologies, athletes can create 3D models of their feet, bodies, or hands, enabling manufacturers to provide equipment designed precisely for their unique dimensions. As such, shoes, grips, and other gears can fit perfectly, enhancing both comfort and efficacy during performance. Furthermore, customization extends beyond mere fit; athletes can choose colors, designs, and branding to reflect personal styles or team affiliations. Creating personalized sports gear boosts morale and provides a psychological edge during competitions. The engagement in the design process empowers athletes, making their sports journey more interactive and satisfying. In team sports, customizing equipment can foster a strong sense of identity, unity, and pride. Additionally, these tailored designs ensure athletes are in optimal physical harmony with their tools, further amplifying advantages in their sport. Overall, the fusion of technology and individualism creates an unprecedented level of player and equipment synergy.

Another area where 3D printing enhances sports equipment design is through rapid prototyping. Manufacturers can now test multiple iterations of designs more efficiently than ever, shortening the time from concept to market. This innovation allows companies to keep pace with the dynamic sports industry, where innovations frequently dictate success. Due to this swift production cycle, feedback from athletes can be integrated immediately into design improvements. Prototyping allows for on-site adjustments and modifications based directly on real-world testing. Moreover, brands can realistically simulate performance metrics and make necessary tweaks to optimize the equipment’s effectiveness. Inventive designs, tested swiftly, mean the best products are available for consumers in a timely manner. In addition to performance evaluation, companies can experiment with new materials and engineering techniques without substantial financial burdens. This flexibility fosters creativity within design teams, encouraging the exploration of revolutionary ideas. Testing and iteration cycles can be improved exponentially, reducing lead times without sacrificing quality. Hence, the marriage of 3D printing technology and sports equipment design drives an era of unprecedented competition and savvy consumerism.

Sustainability in Sports Equipment

Sustainability is a growing concern among consumers today, leading to an increasing demand for environmentally friendly practices within the sports industry. 3D printing aligns perfectly with this ethos by enabling the use of sustainable materials that reduce the carbon footprint of manufacturing. Traditional equipment often generates vast amounts of waste during production, but additive manufacturing utilizes only the necessary materials to create a product. This reduction in waste contributes to environmentally responsible practices in sports technology. Moreover, 3D-printed equipment can be recycled and re-used, reinforcing the potential for a circular economy in sports gear. Manufacturers have begun exploring biodegradable materials that can degrade naturally without harming the environment. As sports organizations look to minimize their environmental impact, adopting 3D printing can enhance their corporate social responsibility. Initiatives promoting green practices resonate well with today’s eco-conscious athletes and fans, who favor brands that prioritize sustainability. Hence, equipment designed with sustainable materials can improve a company’s marketability, making it an appealing choice for both manufacturers and consumers alike.

In conclusion, 3D printing has profoundly influenced sports equipment design, ushering in innovations ranging from customizability to sustainability. The technology provides athletes with an unprecedented level of personalization, allowing them to train and compete with gear that meets their precise needs. Weight reduction and enhanced performance features are essential for athletes competing at all levels, fueling the drive for innovation within equipment design. Furthermore, the rapid prototyping that 3D printing facilitates encourages an environment of creativity and responsiveness in manufacturing. Sustainable practices also help brands position themselves favorably among environmentally conscious consumers. As more research emerges regarding material capabilities and printing techniques, we can anticipate further advancements in this field. The integration of technology within sports continues to pave the way for improvements in performance and experience for athletes. Embracing these changes will undoubtedly lead to a new era of sports equipment production that combines efficiency, sustainability, and performance optimization. As the industry embraces these advances, athletes can expect to benefit from increasingly sophisticated tools that enhance their capabilities and enjoyment of the sport.

Future of Sports Technology

The future of sports technology appears bright, particularly with advancements in 3D printing. As businesses and athletes continue to explore the possibilities of this technology, we can expect further refinements and new applications across various sports. The potential for developing smart gear that integrates sensors and data analytics with 3D-printed components is particularly promising. Sports equipment could soon monitor athlete performance in real-time, allowing for immediate adjustments and improved training strategies. This data-driven approach enhances athlete monitoring and could revolutionize coaching methodologies, informing coaches about optimal practices. In addition to performance tracking, advancements in 3D printing may lead to new materials with superior performance traits, such as increased durability and flexibility. Coaches and athletes who embrace these innovations will create an edge over their competition. Additionally, as global collaborations grow, we can expect innovations to reach athletes in different regions, enhancing their sporting experience with accessible technology. The integration of diverse cultural insights will broaden perspectives in design and functionality, ensuring equipment meets a wide array of needs. In conclusion, 3D printing will play a pivotal role in shaping the future of sports technology, impacting design, performance, and sustainability.

Moreover, 3D printing will likely spur new business models within the sports industry. Beyond simply creating custom equipment, companies may explore on-demand production, where items are manufactured as needed, reducing the need for inventory and storage costs. This approach not only saves money for manufacturers but also allows for faster response times to consumer demands. As athletes and teams push for unique gear tailored to specific events, on-demand options may become increasingly essential. Retailers can also benefit from personalized offerings, providing a new avenue for engaging with consumers and enhancing their brand loyalty. Through collaborations with designers and customization platforms, brands can build stronger relationships with their clients, creating a community around personalized gear. Ultimately, the emergence of 3D printing is reshaping the business landscape in sports equipment design, opening doors for innovation, collaboration, and consumer engagement. With sports technology and manufacturing continually evolving, the horizon for possibilities is expansive. Embracing these changes can result in equipment that doesn’t just meet the needs of athletes but also ignites their passions, ultimately enriching the sporting experience.